Whitepaper

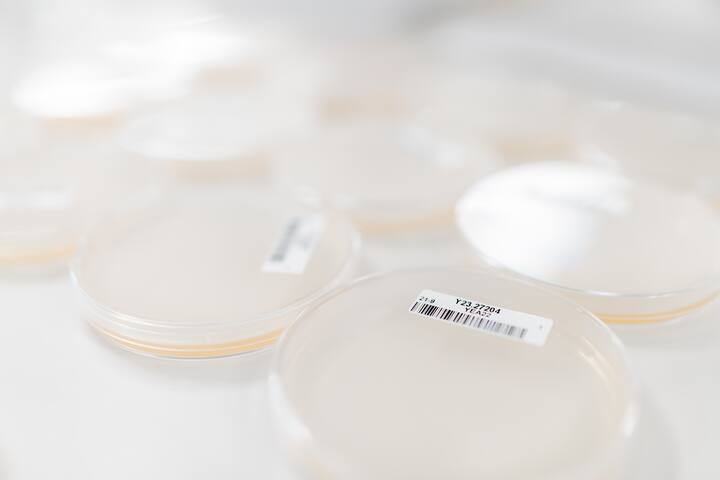

Listeria monocytogenes

Download whitepaper

Discover the 9 control measures for Listeria monocytogenes

The impact of Listeria monocytogenes

Listeria monocytogenes can cause the serious infection listeriosis. Although invasive listeriosis is rare, it is one of the most serious foodborne diseases, with high mortality and hospitalization rates, even in wealthy countries. Contamination with Listeria monocytogenes has far-reaching consequences, both financially and for the image of your product and company.

If a food product is found to be contaminated, you must take immediate action, such as a product recall, to prevent unsafe products from reaching consumers. A professional approach to such a situation can help minimize financial risks and damage to your image.

Criteria

Regulation (EU) 2073/2005 establishes food safety criteria for foodstuffs, including criteria for Listeria monocytogenes in ready-to-eat foods. As a producer, you must ensure that your products comply with these criteria at all times. An amendment to these criteria was published in 2024 (Regulation (EU) 2024/2895). This regulation stipulates that, as a producer, you must be able to demonstrate that your products comply with the criteria throughout their shelf life. Supporting evidence in the form of challenge tests (provocation tests) is an essential part of this.

Multidisciplinary approach

Control measures for Listeria monocytogenes are complex and often multidisciplinary. Essential elements include a clean production area, product analyses, process control, environmental monitoring, and well-trained employees. Inadequate training can result in employees bringing bacteria into the factory. Ultimately, prevention is always better than cure.

These services might also be of interest to you

Baseline measurement of Listeria