Fleet United Kingdom

Normec Crowthorne

Experts in technology solutions and products

Normec Crowthorne is the largest independent supplier of clean air and containment services in the UK and Ireland, providing validation, impartial testing, maintenance, and spare parts to the whole of the UK and Europe. Our offices are located in the UK and Ireland.

Available for all your questions

Do you have a question? Are you curious about the opportunities we see for you or can create together with you? Please contact us.

Normec Crowthorne

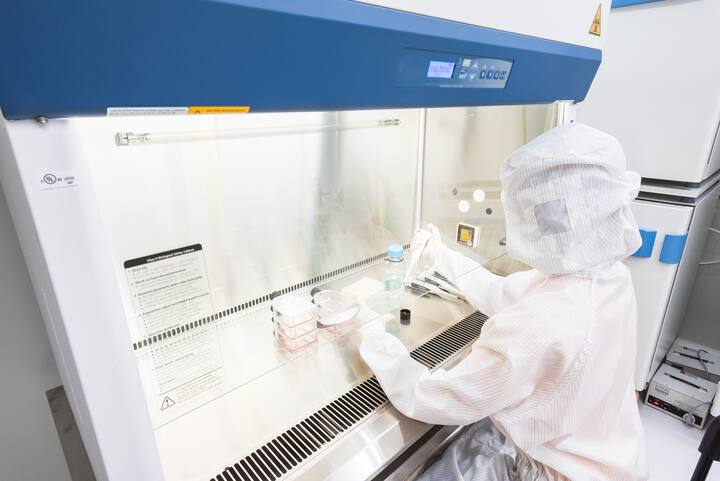

Lab Equipment Testing

Fully independent commissioning and maintenance of containment facilities like biosafety cabinets, laminar flow cabinets, fume cupboards and local exhaust ventilation (LEV) systems.

Parts & Filters

We provide a comprehensive service for the supply of spare parts and filters for cleanroom and airflow equipment.

Independent validation services

We specialise in cleanrooms, containment laboratories, clean air equipment, and fumigation services, offering validation, maintenance, testing, and spare parts across the UK and Europe.

With over 40 years of experience, we have built a strong track record in cleanroom environments, containment labs, microbiological safety cabinets, air handling systems and fumigation solutions. Not being associated with any manufacturer, construction company or supplier of equipment or facilities, we can provide entirely impartial reports on your facility or equipment to keep your staff safe.

Our regionally based engineers are professionally qualified to ensure all equipment is compliant with industry standards and regulations.

We are well-known for our efficient and reliable services including emergency callouts. As proof of our expertise, we are proud to mention that we are actively involved as advisors in the preparation of international standards and that we support major projects as technical advisors at large hospitals, cleanrooms, containment facilities and governmental agencies.

We recognise that every situation comes with its own specific requirements. Get in touch with our experts to discuss yours. We’d be happy to explore how we can support you and provide more detail on the opportunities we offer.

Heritage

Since 1986 Crowthorne developed a long track record of expertise and experience in clean air technology. With the acquisition of Biosafe Safety Services, Bioquell Airflow (Microflow) and Cantel Airflow (Labcaire) in the past years, Crowthorne became the largest UK and Europe independent clean air supplier. Today, Crowthorne is part of the Normec Group, providing access to a broader set of services within life sciences and continued investment in new innovations.

Normec Crowthorne in a nutshell

- 1

1986: Company founded

Crowthorne Hi-Tec Services Ltd was founded.

- 2

1994: Kevin Beauchamp joined Crowthorne

Current MD Kevin Beauchamp joined as General manager

- 3

2003: Crowthorne Group was founded

Acquisition of “Barkman & Purelabs”. Measured Protection Teoranta (Crowthorne Normec Ireland Ltd) was already part of the Group.

- 4

2023: Crowthorne Group joined Normec Group

Crowthorne Group joined Normec Group. At this moment the Crowthorne Group consists: Biosafe Safety Services, Bioquell Airflow (Microflow) and Cantel Airflow (Labcaire)

Certifications & Recognitions

We go for quality. For guaranteed results.

Normec Crowthorne is ISO 9001:2015 certified by NQA for its Quality Management System.

ISO 9001

This certification covers services such as the maintenance and validation of clean air cabinets, microbiological cleanrooms, safety cabinets, cleanrooms, environmental control areas, and occupational hygiene assessments, as well as 24-hour emergency fumigation and related consultancy services.

Related articles

1 Apr 2025

Biosafe – The Only CL3/HL3 Emergency Recovery Plan You Need

When it comes to decontamination and fumigation plans for your lab, the one name you need to know is Biosafe.

Biosafe from Normec Crowthorne Group is an Emergency Recovery scheme for customers with a containment level 3/Hazard Group 3 facility, offering a range of servicing and decontamination response solutions designed for CL3/HG3 laboratories.

7 Mar 2025

What is a KI test?

2 Feb 2025

How often does my safety cabinet need to be tested?

Microbiological safety cabinets are integral in protecting operators, their environment, and often the product being worked with, so it’s vital that they are tested and checked when necessary to ensure that they’re in good working order. Neglecting to do this could mean that they’re not safe to use or compliant with BS EN 12469:2000.

Read on to find out how often your safety cabinet needs to be tested.

30 Jan 2025

How to reduce the risk of post-operative surgical site infection (SSI) rates through regular inspections

21 Sept 2024

Positioning Microbiological Safety Cabinets for Best Performance

Do you want to create a safe and healthy working and living environment?

FAQ

All the most frequently asked questions

The KI-Discus test ensures operator protection when using a microbiological safety cabinet, by producing a fine mist of potassium iodide at specific locations and monitoring the amount detected outside the open front of the cabinet. Test failure can be the cabinet, the filtration system or even the environment i.e. room air conditioning.

Originally LEV systems were required to be tested under COSHH Regulation 9. This was a simple test and still has merit as a means of trending, air velocities, alarm function and evidence of containment. However, standards have moved on and with health and safety stricter, HSG258 is now applied and P601 too.

HSG258 examines the system from the LEV to the outlet after the fan

P601 examines the process the LEV is being used for, to ensure the system is appropriate for the process

A scheduled fumigation is undertaken to fumigate CL3/4 laboratories and has a documented procedure. An efficacy study provides evidence that the overall fumigation procedure provides a 106 log reduction, as preloaded plates are placed around the room ensuring the fumigation process is correct.

A scheduled fumigation gives access to the laboratory, so the placement of the vaporiser and equipment can be placed in the most efficient positions. Additional conditioning can also be added to the room, for example, heating to ensure the temperature is maintained during the entire fumigation process.

An emergency fumigation is different as entry to the room is not permitted without protective equipment, so you have restricted access to precondition the room. We recommend an efficacy study be undertaken in an emergency fumigation situation to confirm the efficacy of the process. We can document the process, so an emergency fumigation protocol can be produced, or we can issue a protocol for the client.

This is a common question. We recommend that a new installation should be tested, together with the laboratory parameters. This provides a baseline and benchmarks test results for future testing. Also if something changes, for example Laboratory pressure, then you can evidence the original setup and know where to get back to.

As P601 work is only part of what Normec Crowthorne offers, not all engineers hold the same qualifications. However, those who are P601-certified bring with them 10 to 15 years of hands-on experience in this area. We also run an ongoing training programme for P601 engineers — and currently, around 30% of our engineering team hold the qualification.

Yes, in most cases, you can still access the lab when using our peroxide systems. However, formalin fumigation requires a longer dwell time and is typically conducted overnight.

Contact

Our offices

Get in touch with one of Normec Crowthorne's offices

Normec Crowthorne | Head Office

Normec Crowthorne | Irish Office

Normec Crowthorne | Scottish Office