‘s-Hertogenbosch Netherlands

Reference Normec Foodcare

References

What customers say about Normec Foodcare

Van Delft Biscuits

Van Delft Biscuits has relied on Normec Label & Specifications for many years

Efteling

Proactive food safety inspections at Efteling

FEBO

Ensuring hygiene at all FEBO locations

Brabant Plant

How Brabant Plant works with Normec Groen Agro Control to ensure consistently high quality

World Premix

World Premix gains customer trust thanks to feed and water analyses

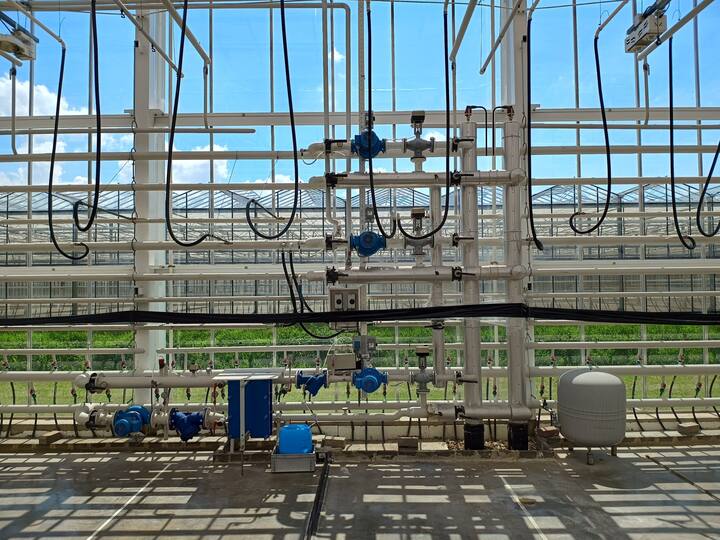

Brabant Plant

Analysing central heating water is invaluable for Brabant Plant, a plant propagation company.

Eytelia

Innovation and efficiency: the digitalisation story of Eytelia and Normec Foodcare Online

Dumea

The intensive collaboration between Dumea and Normec Dumea

Zest

Seamless integration between Normec QC One and Zest's ERP system

Agra Service Nabuurs

Agra Service Nabuurs and Normec Robalab have enjoyed a strong partnership based on trust, flexibility and knowledge for over 30 years.

In a pleasant conversation at the kitchen table of the family business Agra Service Nabuurs, a company specialising in manure distribution, waste transport, container rental and transport, Wilma Nabuurs and her son Wouter talk about their collaboration with Normec Robalab.

Producert

Producert has drinking and spring water samples from its customers analysed by Normec Robalab.

MTS Lucassen

‘Nematode research is more important than fire insurance for our house’

SanLucar

“Our quality inspectors work with QC One software at various locations worldwide.”

Schouten Food

Long-standing partnership between Schouten Food and Normec Foodcare

The collaboration between Schouten Food and Normec Foodcare began years ago. Normec Foodcare continues to support the QA/QC staff in the area of labelling, much to the satisfaction of Frank Sluis, QA/QC manager at Schouten Food.

Special Refining Company B.V.

Time savings of 60 to 80% for Special Refining Company B.V.

Maza

Maza chooses training courses from Normec Foodcare

Guylian

The impact of sensory research on packaging innovation

Vandenbulcke

Vandenbulcke's digital transformation journey with Normec Foodcare Online

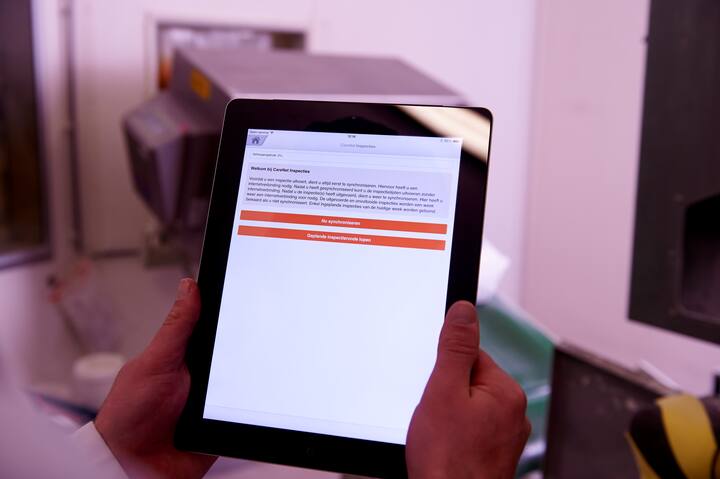

Cavalier

Cavalier takes the step towards QA digitisation

Cavalier develops and manufactures chocolate products without added sugars. The company began digitising its quality control processes at the beginning of this year. In an interview, Felix Verdegem, CEO of Cavalier, discusses the necessity of digitisation and the benefits it has brought to the company.

SA Corman

Q-DNA : Un levier pour professionnaliser la culture de la sécurité alimentaire