Normec Advipro and Legend Biotech are Collaborating on Training CAR-T Technicians and Experts

We are proud to announce that Legend Biotech and Normec Advipro are collaborating on the development and organisation of a process-specific five-day training at the GxP Academy.

The reason for this collaboration is the rapid establishment of the Legend Biotech production organisation in Belgium. Training large numbers of technicians and experts to prepare them for the state-of-the-art production facility in Zwijnaarde, Belgium, is of utmost importance for both quality and operational purposes. This facility will house the innovative CAR-T cell cancer therapy production.

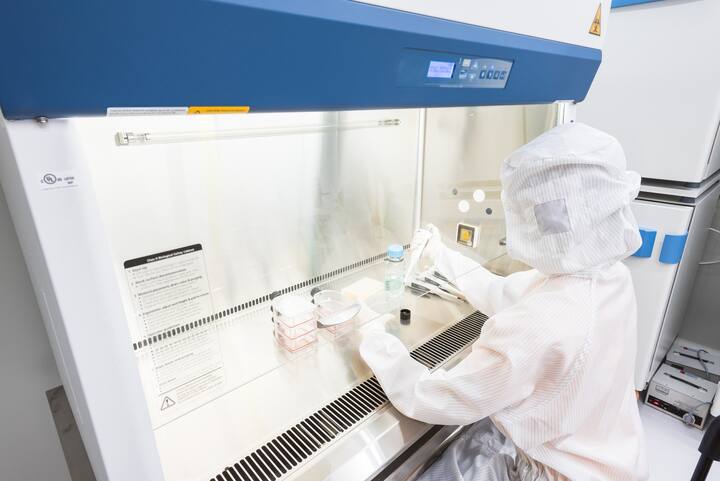

As a new biotech company, developing and training operators and building leading capabilities in the industry is key to success. Furthermore, Legend Biotech currently has no facilities in Europe, as the construction of the Gent facilities is still ongoing. The solution to both challenges is provided by the GxP Academy, Normec Advipro’s unique high-tech training facility with a fully operational cleanroom built according to international GMP standards. This is the ideal environment for Legend Biotech operators to be trained in their procedures. In collaboration with Legend Biotech's production leader, training manager, QA, and SMEs, Normec Advipro has developed a five-day training program, "Introduction to GMP for Legend Biotech (GMP for ATMP, Contamination Control and Environmental Monitoring, Gowning and Aseptic Procedures)", specifically tailored to Legend Biotech’s production processes."

Alain DeloofManager GxP Academy

"We are extremely excited to collaborate with Legend Biotech on this exciting journey. It was an intensive process working with various teams within Legend Biotech to determine and develop the diverse topics in the program. Production lead Sarah laid the initial foundation, and we worked closely with the training manager and process owners to develop both the theoretical and practical modules. This enables the trainees to gain as much knowledge as possible and then apply it in practice in our operational cleanrooms." Alain Deloof – Manager, GxP Academy

What's on the agenda?

GMP with a focus on CAR-T cell therapy production. Additionally, a workshop on their production process, taking into account EudraLex Volume 4, Part IV (specific to ATMP).

Working in a cleanroom: contamination control, what is a cleanroom, different types of cleanrooms, what constitutes contamination of a product, environmental monitoring, cleaning and disinfection, etc.

We will cover gowning procedures and how the operators can apply these in their own cleanroom. The entire gowning process will be addressed, from Grade D to an aseptic production environment.

Process-specific training: Critical steps in CAR-T cell therapy, filling and finishing, visual inspection, etc.

About CAR-T cell therapy:

CAR-T cells are genetically modified T cells that express a chimeric antigen receptor (CAR), a three-part hybrid protein: a tandem antigen-binding domain from an antibody, a transmembrane domain, and the signalling elements of the T-cell receptor complex. The CAR antigen-binding domain targets tumour cells that express the target cell surface antigen. Once the CAR has found its target, it transmits molecular signals via its intracellular modules to activate CAR-T cells, resulting in the destruction of the target tumour cells.

GxP Training Tailored to Your Procedures?

More about Normec Advipro

Normec Advipro

Lille Belgique

Vous souhaitez créer un environnement de travail et de vie sûr et sain ?