Testing and release for pharma and life sciences

Pharmaceutical Impurity Profiling

We offer cGMP-certified elemental impurities analysis for pharmaceutical manufacturers, drug substance producers, importers, and wholesalers. Our testing is performed according to the USP <232>/<233>, EP 2.4.20 / 5.20, or your own validated method fully aligned with the latest ICH Q3D guidelines.

With advanced instrumentation, we help you detect, quantify, and control trace elements in your raw materials, excipients, and finished drug products from low parts per trillion (ppt) to high parts per million (ppm).

Why choose us?

cGMP-certified laboratory

Testing aligned with USP, EP, and ICH Q3D

Fast turnaround and expert support

In-house QA team ensures compliance and reliability

Flexible solutions tailored to your needs

Comprehensive Pharmaceutical Impurity Profiling for Regulatory Confidence and Patient Safety

Ensure the highest standards of pharmaceutical quality with our comprehensive impurity profiling services. We offer advanced analytical solutions to identify, quantify, and control impurities in drug substances and products, supporting your compliance with ICH guidelines and regulatory expectations worldwide.

Our specialized services include:

Elemental Impurities Analysis (ICH Q3D): Using state-of-the-art such as ICP-MS, AAS, and AES and validated methods, we analyze trace levels of chemical elements to ensure compliance with global safety thresholds.

Residual Solvents Testing (ICH Q3C): Our gas chromatography-based methods accurately quantify Class 1, 2, and 3 solvents, supporting safe manufacturing and patient use.

Nitrosamine Risk Assessment & Testing: With growing regulatory scrutiny, we offer sensitive detection and quantification of nitrosamines, ensuring your products remain within acceptable daily intake limits.

Cleaning Validation & Verification: Ensuring that effective cleaning processes remove product residues, impurities, and cleaning agents. Using validated analytical methods, we verify that your manufacturing equipment meets stringent regulatory and safety standards.

Let’s bring safer pharmaceuticals to market—as reliable joint partner

Our Techniques for Elemental Impurity Testing

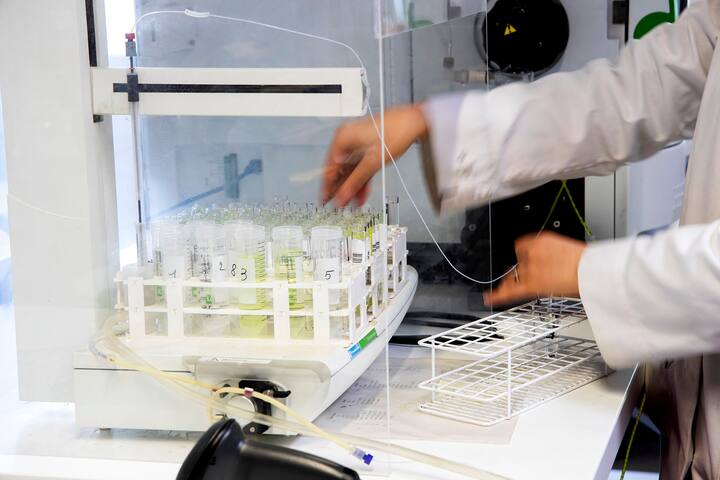

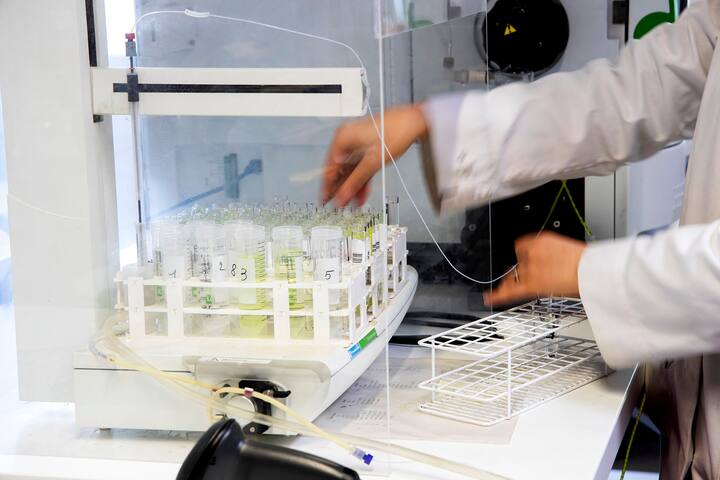

We use several validated methods to test both organic and inorganic materials, in aqueous and non-aqueous matrices. Sample preparation is performed using microwave digestion. Our elemental impurity testing is commonly used in: - Pharmaceutical manufacturing: ensuring raw materials and drug products meet global safety standards - Drug substance manufacturing: controlling contamination risks and staying compliant - Import & wholesale of pharmaceutical products: verifying quality before release into regulated markets

Inductively Coupled Plasma – Mass Spectrometry (ICP-MS)

- Highly sensitive multi-element analysis (24+ elements) - Conforms to USP <232>/<233> and EP 2.4.20 - Detects trace metals and non-metals from ppt to ppm - Equipped with collision cell technology for accurate results in complex matrices - High Matrix Introduction (HMI) allows direct testing of samples with high dissolved solids

Atomic Absorption Spectroscopy (AAS)

- Quantitative analysis of metals as minor or trace elements - Supports flame absorption, graphite furnace, and flame emission techniques

Atomic Emission Spectrometry (AES)

- Suitable for simultaneous multi-element detection - Often used in combination with AAS for flexible application

These services might also be of interest to you

Importation testing

Stability testing and sample storage

Pharmaceutical quality control testing

Leading companies in this service

Normec Synergy Health

Nieuwegein Netherlands

Normec Heppeler Institute

Lörrach Germany