Allergen analysis: best practices

More and more people have food allergies. Think of allergies to milk, nuts, eggs or gluten. For food producers, it is therefore very important to prevent cross-contamination with allergen-containing substances during production in foods that do not contain these allergens.

The article below explains which methods are suitable for testing for the presence of allergens. And above all: how to apply them in a smart and practical way.

Why allergen management is so important

Incorrect allergen labelling can have serious consequences. It can lead to product recalls, fines from regulators such as the NVWA and FAVV, or even worse, health problems for allergic consumers. It is therefore very important to know whether the amount of allergens in the product is above the reference values (RfDs) in order to include the correct allergen information on the label.

Methods for testing for allergens in the food industry

Controlling allergens in food production requires targeted checks on raw materials, surfaces, equipment and end products. There are four commonly used testing methods, each with its own applications, advantages and limitations.

Rapid tests, such as test strips, are fast, simple and suitable for line release or raw material control. However, they are usually only qualitative and sensitive to interference from fat, pH or heating. They are useful on the work floor, but less reliable for complex products.

Surface swabs are used after cleaning to detect cross-contamination. They are effective for hygiene checks, but do not provide certainty about the end product. Results are highly dependent on correct execution.

Rinse water analyses are suitable for CIP systems and assess overall cleaning. They provide an indication of residual allergens, but are diluted and less sensitive than product analyses.

Product analyses (via ELISA, PCR or LC-MS) offer the most certainty about the presence of allergens in the end product. They are accurate but time-consuming and sensitive to processing influences or matrix effects.

In practice, a combination of methods is most effective: rapid tests and swabs for immediate checks and product analyses or rinse water for more in-depth verification. Ensure proper training, correct method selection and regular validation to keep allergen risks manageable.

A good test starts with a good sample. Whether you take a swab from a machine, test a product or analyse rinse water, the way you do it determines the result.

Which product analyses can detect allergens?

Allergens can be detected in various ways. A number of methods are explained below. Each method has advantages and disadvantages. Choosing the right technique depends on the product, the process and what exactly you want to measure.

ELISA (Enzyme-Linked Immunosorbent Assay

The ELISA method is one of the most commonly used techniques in the food industry for detecting allergens. It is a type of “test kit” that recognises allergen proteins. It is fast and often very accurate. This method is based on immunological detection and is particularly suitable for detecting protein-based allergens such as milk, sesame, egg, peanut, soy, gluten, lupine, nuts, fish and shellfish.

Operation and application

ELISA uses specific antibodies that bind to an allergen protein. When this binding occurs, an enzymatic colour reaction is triggered. The intensity of the colour is proportional to the amount of allergen in the sample and is measured with a microtiter plate reader (spectrophotometer). An incubator and pipettes are required to perform the analysis.

The method is not suitable for detecting allergens whose protein structures have been severely degraded, for example by heat treatment or fermentation. DNA-based allergens cannot be detected using ELISA either.

Practical Use

Performing an ELISA test in the laboratory involves a few steps:

What is required?

Microtiter plate reader (spectrophotometer), incubator, pipettes.

Result? Color change, readable by quality assurance staff. The results are expressed in mg allergen per kg or mg allergen per kg of product, depending on the kit and therefore sometimes require conversion.

Requires basic pipetting skills and hygienic working. Ready-to-use kits with simple instructions are also available.

Advantages and Disadvantages

A significant advantage of ELISA is that commercial kits are available for a wide range of allergens. Furthermore, the method is suitable for quantitative analysis, making it valuable for monitoring and regulatory compliance. These advantages are offset by some limitations. ELISA is sensitive to matrix effects: the composition of the food product (such as fat content, pH, or processing) can complicate protein extraction, leading to underestimation of the allergen concentration. In addition, cross-reactions can occur, with antibodies also reacting to related proteins that may not be harmful. Changes in protein structure, for example, due to heat or enzymatic degradation, can reduce antibody recognition and thus lead to false-negative results. Furthermore, we know that ELISA mistakes peas for soy. And that fish, celery, mollusks, and sulfites cannot be detected by ELISA.

PCR (Polymerase Chain Reaction)

Well-known from the coronavirus era; this technique searches for the DNA of allergens. It's useful when proteins have been altered by heat. Unlike ELISA, PCR doesn't focus on proteins, but on the genetic material of an allergen. This makes PCR particularly suitable for allergens such as shellfish, fish, celery, mustard, lupine, and mollusks. It can also be used for soy, peanuts, eggs, tree nuts, sesame, and as long as sufficient DNA is still present in the product.

Operation and Application

PCR works by amplifying (multiplying) specific DNA fragments using primers that target characteristic DNA sequences of an allergen. During the process, these fragments are multiplied in a thermal cycler. In real-time PCR, this process is monitored via fluorescence, which provides an indication of the amount of DNA in the sample.

This method is particularly useful in products where proteins may have been degraded or modified, but where DNA is still present. However, PCR is not suitable for products that have been processed in such a way that the DNA has been completely degraded or removed, such as highly refined oils.

Practical Use

This test is only for producers with a fully equipped molecular biology lab and trained personnel.

What is required?

Thermocycler (real-time PCR), DNA extraction equipment, contamination prevention.

Result? Ct values (cycle threshold), requiring interpretation.

Due to its sensitivity to contamination and the complexity of the procedure, PCR is usually outsourced to specialized laboratories.

Currently, it primarily provides a qualitative result. Quantitative determination is possible with a conversion factor. This establishes the link between DNA and protein.

Advantages and Disadvantages

PCR is highly sensitive and capable of detecting low levels of allergen DNA, even in complex or highly processed products. It is also less dependent on the integrity of protein structures. However, PCR does not provide information about the presence of functional or intact proteins—and therefore not directly about allergenic activity. The allergens egg, milk, and sulfite cannot be detected by real-time PCR.

The method requires specialized equipment and experience. In some cases, components of the food can inhibit PCR reactions (so-called PCR inhibitors), making detection less reliable.

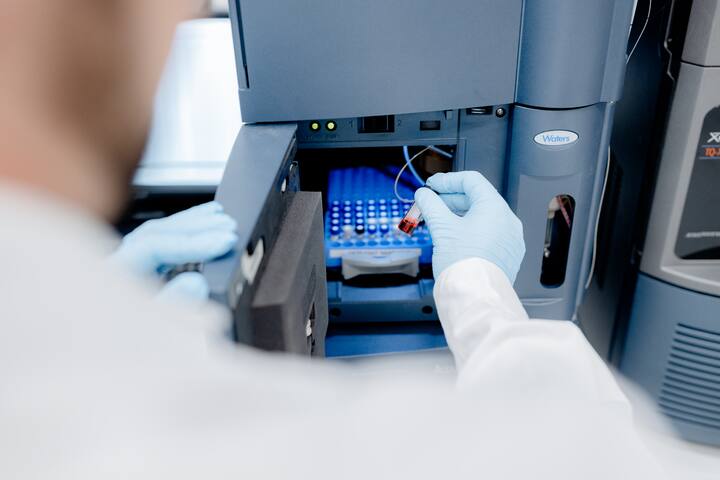

LC-MS (Liquid Chromatography – Mass Spectrometry)

LC-MS is an advanced analysis technique that can identify and quantify specific peptide fragments of allergenic proteins. This method is widely applicable for common allergens such as milk, egg, peanut, tree nuts, gluten, and soy.

Operation and Application

With LC-MS, proteins are extracted from the sample and then enzymatically broken down into small peptide fragments (often via trypsin digestion). These peptides are separated via liquid chromatography (LC) and then analyzed in a mass spectrometer. The combination of the mass and charge of the peptides allows the detection of specific fragments of allergenic proteins.

This method is highly suitable for analyzing products containing allergens, as the technique can also identify partially degraded proteins.

Practical Use

This test can only be performed by external specialized laboratories.

What is required?

LC-MS/MS instruments, enzymatic digestion, data analysis software.

Result? Highly accurate quantification in ng/g or μg/g.

High investment, technical complexity, and the need for validation make this method unsuitable for routine use by manufacturers themselves.

Advantages and Disadvantages

LC-MS offers exceptional specificity, minimizing the risk of cross-reactions. It is also possible to detect multiple allergens in a single analysis (multiplex). Furthermore, LC-MS can detect partially degraded or processed proteins, which is not always possible with ELISA.

These advantages are offset by higher costs and greater technical complexity. The method requires specialized equipment and expertise. Matrix effects—such as fats and salts—can also affect the ionization of peptides, which can reduce the accuracy of the analysis.

Flow cytometry (microsphere-based)

Flow cytometry is less frequently used in the food industry but is gaining popularity due to its multiplex detection capabilities. This technique uses microscopic beads (microspheres) coated with specific antibodies targeting allergenic proteins.

Operation and Application

When a food sample is mixed with these microspheres, any allergens present bind to the beads. A second antibody with a fluorescent label is then added. The amount of fluorescence is measured in a flow cytometer, with each microsphere analyzed individually.

This method is suitable for protein-based allergens and offers similar applications to ELISA, but with the ability to measure multiple allergens simultaneously.

Practical Use

These tests are only used by large companies with advanced R&D facilities.

What is required?

Flow cytometer, microsphere kits, knowledge of data analysis.

Result? Fluorescence intensity (MFI), semi-quantitative to quantitative.

Less suitable for production control, more suitable for research purposes or validations.

Advantages and Disadvantages

A major advantage of flow cytometry is the possibility of multiplexing: multiple allergens can be detected simultaneously in a single analysis. The method is more sensitive than standard ELISA and offers greater flexibility with complex matrices.

The disadvantages lie mainly in the cost and complexity. Flow cytometers are expensive and require specialized training. Furthermore, this method is less common in routine practice in the food industry.

Although less sensitive to some matrix effects than color reactions (such as in ELISA), certain food components can still influence binding or fluorescence, particularly fats or acidic pH. Here too, processed or denatured proteins can influence recognition.

Beware of "false" results

Sometimes tests produce incorrect results: they say an allergen is present when it isn't (false positive), or they say it's not an allergen when it is present (false negative). Causes can be due to product processing, incorrect test kits, or interfering substances in the sample. Therefore, it's important not to rely on a single test result but to repeat it at least twice.

The role of accreditation

Reliable laboratories operate according to strict quality regulations (e.g., ISO 17025). This means their tests are validated, staff are well-trained, and results are reliable. The Normec Group laboratories operate under accreditation, and even when analyses are outsourced, Normec Foodcare works exclusively with these types of laboratories.

Lab Advice

Which method is best for each allergen type? See below for the lab's advice**.

Gluten: ELISA

Crustaceans: ELISA/PCR

Egg: ELISA

Fish: PCR

Peanut: ELISA

Soy: ELISA

Milk: ELISA

Nuts: ELISA

Celery: PCR

Mustard: PCR

Sesame: ELISA

Sulfites: Steam distillation

Lupine: ELISA/PCR

Molluscs: PCR

**Note: this is an estimate; this advice is based on the information available on the publication date (July 2025) of this article. Always consult the lab before scheduling and performing an analysis.

What can Normec Foodcare do for you?

At Normec Foodcare, everything is about food safety, quality and practical advice. Whether you want to know which testing method to use, how to make your processes safer or how to comply with legislation. Normec Foodcare's experts are happy to help you.

Don't want to worry about allergens? Let us help you with:

Tailored advice

Practical training

Reliable laboratory tests

Legislative and regulatory support